Project data

Type

Authors

Status

Years

Made

Yes

Replicated

No

Cost

The Stethoscope is one of the most basic medical tools. It allows a trained medical professional to diagnose issues with the heart and lungs. Stethoscopes come in a range of prices and quality, but all are breakable. This Stethoscope only requires some surgical tubing or similar airtight tubing and 3D printed parts.

Bill of Materials BOM

3D printer

Filament

STL and/or OpenScad files

Thingiverse Media:Stethoscope ears.scad

Media:Stethoscope.scad

Surgical tubing Tools needed MOST Delta RepRap or similar RepRap 3-D printerKnife or scissors Skills and knowledge needed No special skills needed to build, To use this device propertly takes some training.

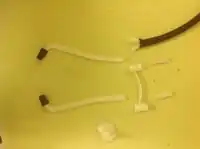

Technical Specifications and Assembly Instructions There are 7 seperate prints for this device listed below with there print times (depending on your printer and settings)

Bell

Approximately 2 hours

Y tubing joing

Approximately 1/2 hour

2 small tubes

Approximately 1 hour each

Cross piece

Approximately 3 hours

2 earpieces

Approximately 4 hours each

Assembly time depends on how much post-printing corrections you need to do. Some filing or sanding may be necessary for a great fit.

Cut the tubing to desired length,

About a 1.5 feet from the bell to the Y joint

2 at about 4 inches from the Y joint to the small straws

2 small tapered pieces to act as ear buds on the end of the long earpieces

Simply fit the pieces together, I did not use any glue but that is an option. Common Problems and Solutions For a really tight plastic on plastic fit, some sanding or filing will need to be done. Cost savings Costs

Plastic at $25 per kilogram, 45 grams, $1.13

Rubber tubing $2.30 per foot, 2 feet, $4.60

Commercial Equivelent

Savings between $2.26 and $69.27

Page data

Authors

License

CC-BY-SA-3.0

Organizations

Cite as

Brett Barker (2014–2024). "Stethoscope" . Appropedia. Retrieved November 28, 2025 .